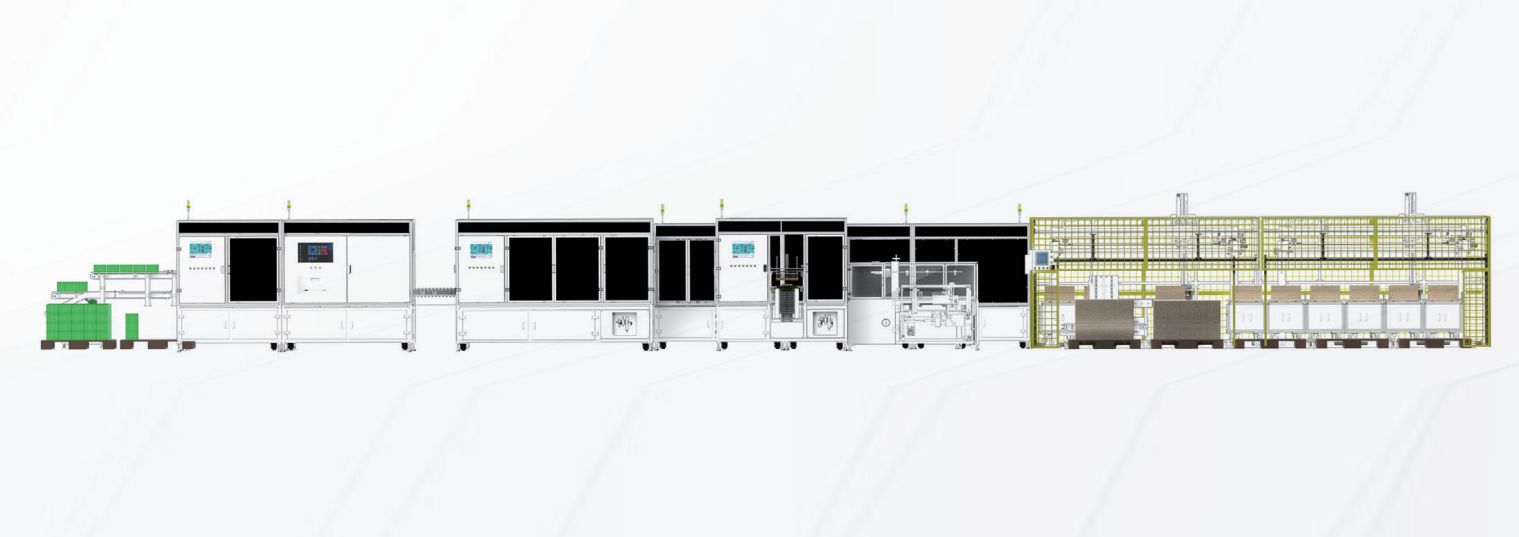

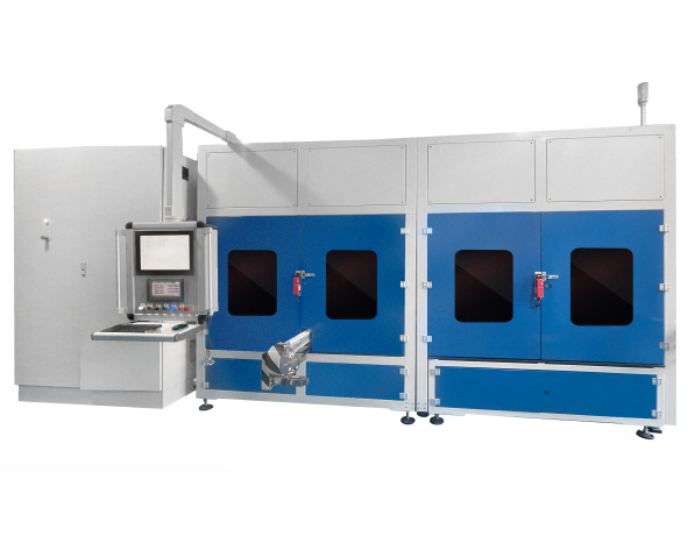

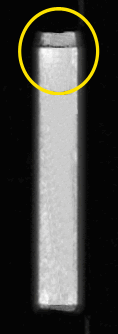

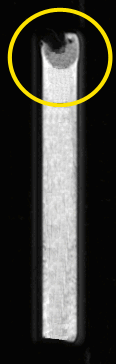

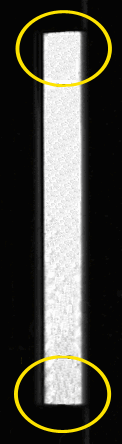

AOI Machine for Needle Roller Appearance Defects(Choyo-R21)

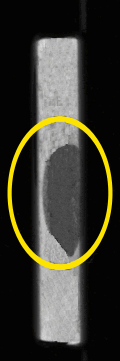

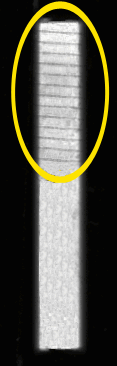

Optical automatic detection equipment for appearance defects of needle roller is used for 360° appearance defects detection of bearing needle roller. It can detect defects such as grinding marks, rusty marks, collapsed face, marks like a knife etc, as well as the measurement and out-of-tolerance sorting of needle roller length. The detection speed can reach 60,00pcs /h, and the high-speed appearance detection can be applied to the wired appearance detection. The device integrates dimension measurement and out of tolerance function at the same time, can effectively eliminate the length out of tolerance.

Machine Vision

Machine Vision Bearing

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS