-

Product

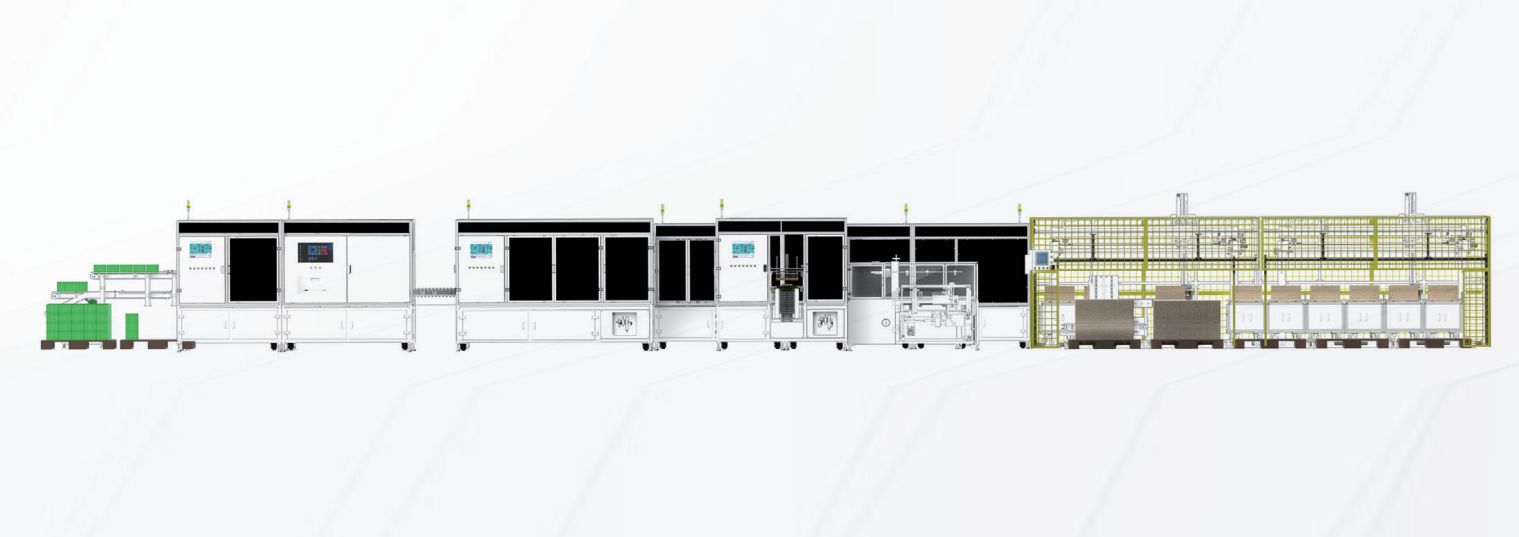

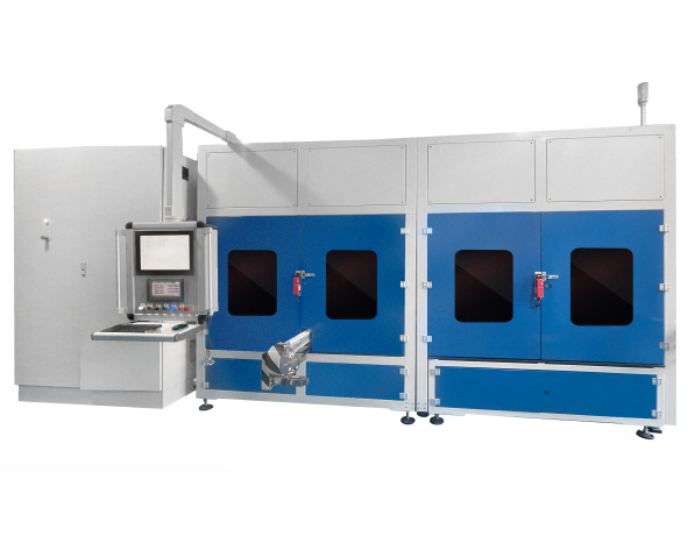

Machine Vision

Machine Vision Bearing

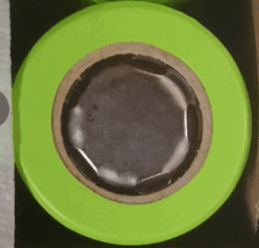

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS -

Solution

-

About Us

-

Service

-

News

- Join Us

- Contact

- 中